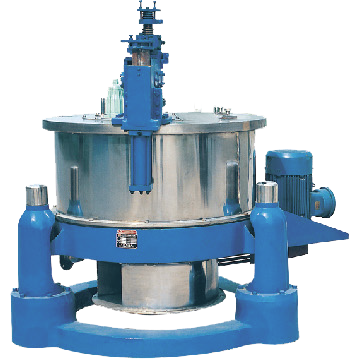

Automatic Discharge Basket Centrifuges greatly increase the capacity by eliminating the manual process of removing the solid cake from the centrifuge basket. Slury is added to the rotating basket and liquid flows throught the filter material. Solids are collected on the inside of the basket forming a cake. If applicable the cake can be washed in place. When the centrifuge has built a sufficent cake, the peeler arm is deployed and the cake is removed from the basket wall and drops through the bottom of the basket. These machines come in a cast iron or stainless steel structure and are powered with a hydralic power unit and PLC control cabinet.